28 Mar 5 modular benefits

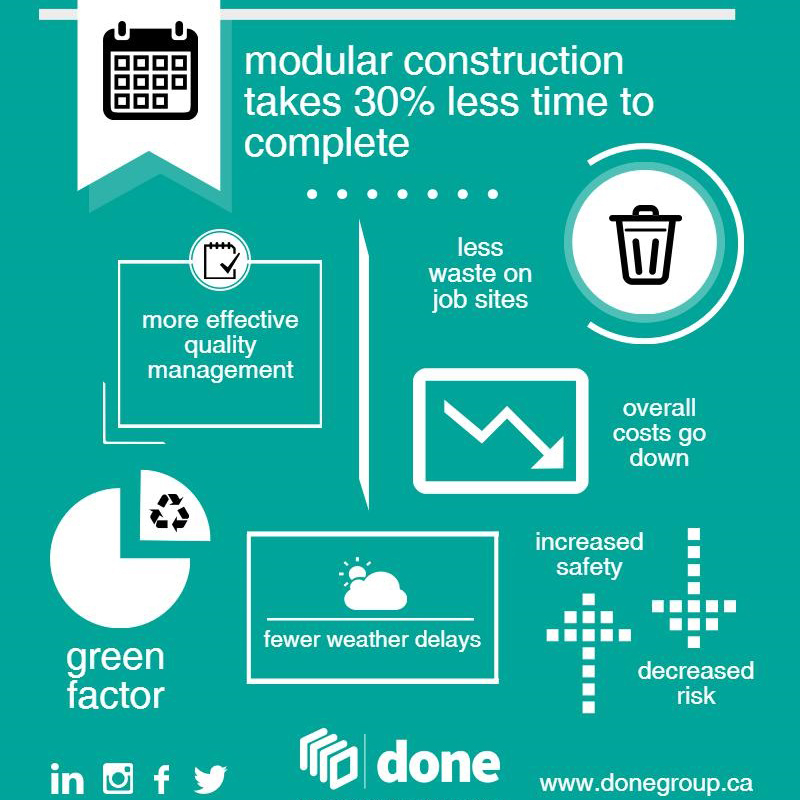

It’s becoming more important to build smarter; more efficiently and sustainably without sacrificing quality. We’ve chosen modular and this is why:

Time Savings. While traditional builds require a foundation before exterior walls are raised, modules are built off-site at the same time the foundation is being laid. Picture a module, with the electricity wired and the interior walls painted, being lifted onto the structure. The overall time savings on a modular product can be over 30%.

Quality Control. Every single module is engineered to be load-bearing and able to withstand being trucked from the factory to site and craned into place. Quality checks during production ensure each module conforms to code.

Reduced Site Disruption. A reduced schedule also means reduced disturbance to the surrounding environment. Less time spent on site means less noise, pollution and waste.

Increased Productivity. We can ensure maximum productivity in the factory, as contractors have all the necessary tools and materials to get the job done at hand, in a safe environment with limited exposure to adverse weather conditions and other risks.

Overall Cost Savings. With so many details of the modules determined up front, expensive changes can be avoided. Financing costs can be reduced thanks to reduced construction time.